Article

29. desember 2025

Saga Fjordbase – 25 years of collaboration, change, and world-class logistics

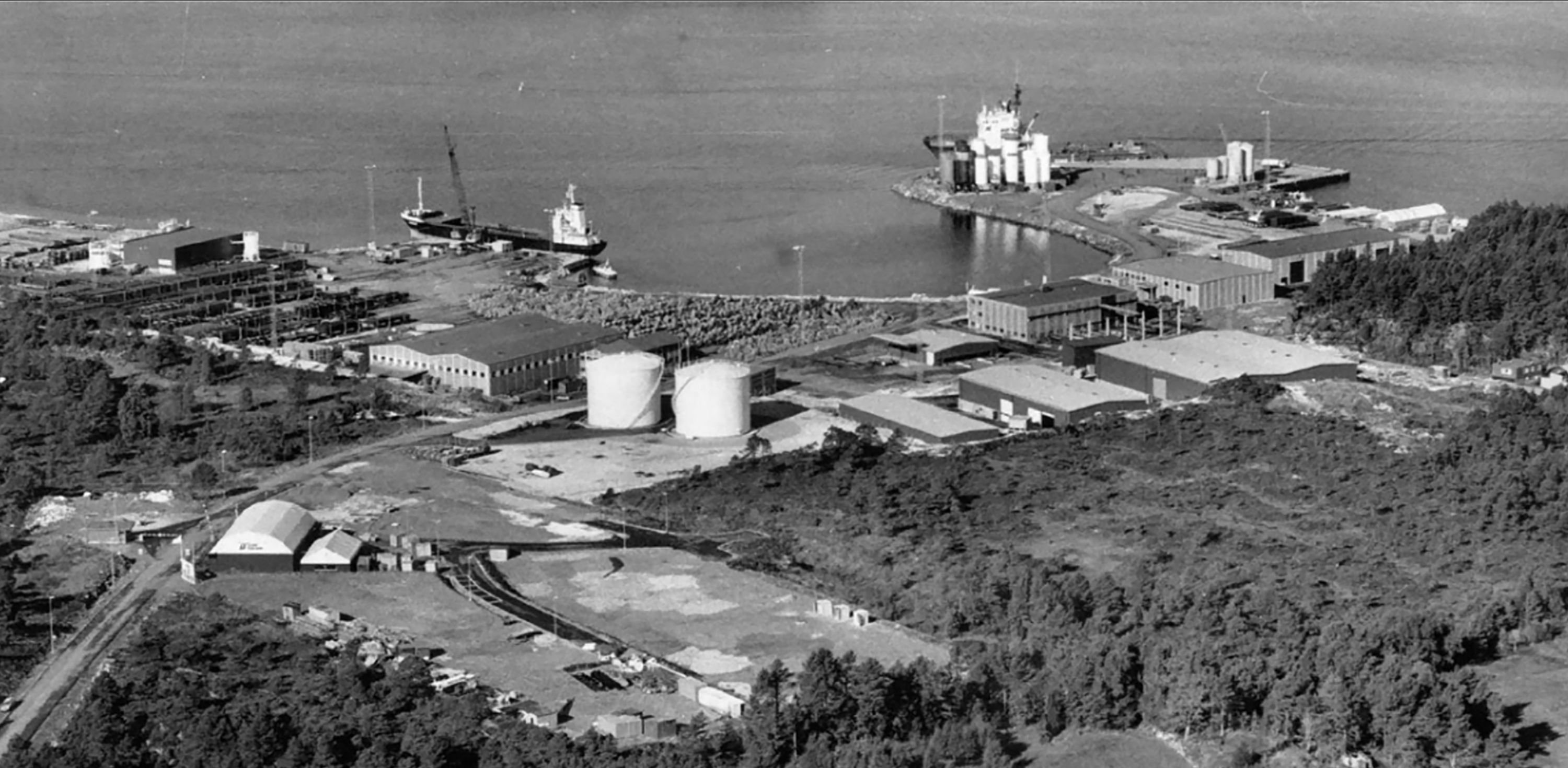

Saga Fjordbase markerer 25 år med omstilling, samarbeid og målrettet forbedringsarbeid. Foto: Emil Rasmussen

Spesialrådgiver Anne Kari Husevåg Hereid har vært med siden starten av Saga Fjordbase. Hun har også jobbet som leder luft og sjøtransport, og leder stab i Saga Fjordbase. Her med administrerende direktøy Erlend Toftesund.

As Saga Fjordbase AS marks its 25th anniversary, it is about more than celebrating a company. It is a celebration of an entire environment that, through continuous development, has created jobs, built expertise, and strengthened the industrial community at Fjord Base. The story of Saga Fjordbase is a story of transformation, collaboration, and focused improvement work. It is also a story about people who have stood together through both good times and demanding periods—and who today are helping shape a new era defined by digitalisation, greener operations, and smarter logistics.

This journey began when employees from the former Saga Petroleum, together with Per Nødseth and Oddgeir Igland through INC Invest, made a bold decision to secure jobs and carry the professional environment in Florø forward. Twenty-five years later, Saga Fjordbase stands as a modern, forward-leaning logistics company—and a central part of Fjord Base Group.

From an oil company to a local logistics company

At the turn of the millennium, employees at Fjord Base were in the middle of major change. Saga Petroleum had been hit hard by low oil prices in 1999. The company was eventually sold to Hydro and later to Statoil. As a result, the local organisation that had been part of the oil company disappeared, and employees faced a crucial choice: Would competence and jobs disappear—or would they build something new?

The answer came on 1 January 2000, when Saga Fjordbase AS was established. Initially, the company was owned 50 percent by the former employees and 50 percent by INC Invest, led by Per Nødseth and Oddgeir Igland. Two years later, INC took over full ownership. The goal was clear: to secure jobs, maintain a strong professional environment, and create a flexible, future-oriented logistics organisation at Fjord Base.

Anne Kari Husevåg Hereid is one of those who has been there from the very beginning. She describes the period as an exciting journey marked by unity, determination, and major transformation.

“Over the years, we have stood together through both good times and changes. The strong sense of community and the willingness to solve challenges have made the journey both memorable and meaningful, and I am proud of everything we have created together,” says Anne Kari.

The early years – transformation and new requirements

The transition from being part of a large oil company to becoming a supplier in a competitive market was demanding. When much of Hydro’s activity was moved to Bergen in 2002, and Statoil took greater responsibility for its own logistics and transport, Saga Fjordbase had to adapt quickly.

The period was tough, but also valuable. Documentation and work processes had always been important, but requirements now became even stricter. Saga Fjordbase had to further professionalise its work, streamline routines, and compete more clearly on both price and quality. This triggered new ways of working, structured improvement efforts, and a gradual development of the organisation.

Those first years became an important maturity phase that strengthened the company and laid the foundation for the road ahead.

Growth, skills development, and new services

From the mid-2000s, activity levels at Fjord Base rose steadily. New field developments, including Gjøa, created high workload and a need for greater capacity and stronger expertise. Saga Fjordbase responded by developing new services and building specialist environments within terminal operations, warehousing, maintenance, subsea, maritime services, and OCTG.

At the same time, HSE work was significantly strengthened. For Saga Fjordbase, HSE comes down to one fundamental thing: Everyone working at Fjord Base must get home safely every day. This is the company’s licence to operate, and it shapes all work processes. During this period, substantial investments were made in quality systems, process improvements, safety routines, and ongoing competence development.

The combination of increased HSE focus and targeted skills development made Saga Fjordbase an increasingly robust and professional organisation—well equipped for more complex and demanding operations.

Together, we get it done

Saga Fjordbase would likely not be what it is today without Florølandets Transportarbeiderlag (FTA). Since its establishment in 1985, FTA has been absolutely essential for all handling of loading, unloading, and cargo flow on the quays at Fjord Base.

Their working days are varied, hands-on, and often physically demanding. They are at the front of the logistics chain and handle everything within terminal services. FTA is closely integrated with Saga Fjordbase—which holds overall responsibility—in all quay-side operations. Together, they ensure that everything arriving at and leaving Fjord Base is handled safely, efficiently, and correctly.

FTA has also been an important arena for recruitment and integration. Many who work at Saga Fjordbase today started their careers here—as part-time employees, students, apprentices, or young people wanting to try themselves in the base environment. The flexibility in working hours and tasks makes FTA a natural entry point into the logistics profession.

Together, Saga Fjordbase and FTA have ensured that the supply base in Florø has always been set up for high pace, a high degree of flexibility, and large volumes.

OCTG operations

A significant part of Saga Fjordbase’s activity is linked to OCTG (Oil Country Tubular Goods), which includes pipes and tubular components used in the oil and gas industry. About once a month, a pipe carrier arrives from Japan with new pipes that are stored at the base before being distributed onwards to fields in the North Sea.

Unloading a pipe vessel is one of the most complex operations we perform, and we handle it with high precision and well-established routines. Over many years, Saga Fjordbase—together with the actors at the base—has built solid experience, strong routines, and a strong HSE focus to carry out the work safely and efficiently. Pipe handling is performed by several companies, including Equinor’s OCTG centre, and the collaboration works very well.

When pipes are stored and moved around the site, they are placed in cradle frames that ensure stability and safe handling. With pipes in cradle frames, a terminal tractor can move up to 100 tonnes in a safe and efficient way. The cradle frames were developed in the 1980s and are a strong example of early innovation at Fjord Base—a solution that is still absolutely critical to our operations today.

A new direction – Lean and Green and cross-base collaboration

After a demanding period of low oil prices, Saga Fjordbase set a new course in late 2016. The company established the improvement programme Lean and Green, aimed at mapping value streams, reducing waste, and strengthening collaboration among all actors at Fjord Base.

This work has created a stronger culture for working smarter, more efficiently, and more collaboratively towards a shared goal. It has led to important improvements in work processes, coordination, and environmental footprint—and has laid the foundation for several of the digital innovations and competence initiatives we have launched, and will continue to launch.

Saga Connect – the digital revolution

The Lean and Green effort became the starting point for one of Saga Fjordbase’s largest digital initiatives. The result was Saga Connect, launched at ONS in 2022. The platform has changed how the actors at Fjord Base collaborate. Information is now shared in real time among everyone involved, and the system has replaced emails, Excel spreadsheets, and many of the phone calls that were previously necessary to maintain oversight of logistics.

Workflows are clearer, more standardised, and consistent for everyone. All activity that takes place at the base—between suppliers and customers, and between terminal operations and vessels—is now coordinated through a single collaboration platform.

The impact came quickly. In the first year alone, vessel time alongside the quay was reduced by 26 percent, and emissions were cut by around 300 tonnes of CO₂ per month. A total of 2,560 operations ran smoothly through the system.

In a short time, Saga Connect has become a modern logistics tool with more than 220 users across 70 companies—developed and operated locally by our subject-matter experts in Florø.

“Saga Connect has not only been a digital success—it has demonstrated our ability to deliver and enable smart, future-oriented logistics solutions. Cross-company collaboration increases value creation that benefits the customer. We connect people, data, and suppliers in one system—for faster flow, better precision, and real customer value,” says Erlend Toftesund, CEO of Saga Fjordbase.

Leading organisation – role-based logistics

Another important improvement initiative at Saga Fjordbase is the role-based logistics model, developed in close collaboration with Shell Norway and the Knarr supply operations. Instead of traditional teams, work is now organised into cross-disciplinary roles that follow the entire logistics lifecycle—from planning begins until the assignment is completed.

This way of working has delivered major gains. Saga Fjordbase now handles the same volume of work as before, but with only one third of the resources. Logistics is standardised across customers, which has reduced costs significantly and enables flexible yet predictable deliveries.

Today, the model is the very foundation of operations in Building 75 – Logistics Center of Excellence. From here, Saga Fjordbase manages all internal logistics at Fjord Base: cargo flow, coordination, warehouse operations, terminal operations, drilling campaigns, and exploration drilling. In addition, all quay and vessel operations are coordinated from here.

With this structure, Saga Fjordbase functions as a complete “one-stop shop” for customers and operators, contributing to safe, seamless, and cost-efficient operation of the entire Fjord Base.

National collaboration and greener operations

Saga Fjordbase started as an independent, solid company in 2000. Today, the business is an integrated part of Fjord Base Group, together with the property company Fjord Base AS. This structure creates strong day-to-day synergies. When operations, logistics, property, and development are gathered within one group, customers, operators, and suppliers experience a more holistic and efficient service. It also makes us better equipped to meet future needs—both on land and out on the fjord.

Even though activity on the Norwegian continental shelf is expected to decline over time, the need for smarter, safer, and more cost-efficient logistics is increasing. This has strengthened collaboration between Saga Fjordbase and Equinor. Through Equinor’s improvement programme NLP (Norwegian Continental Shelf Logistics Project), Saga Fjordbase contributes experience, input, and concrete measures that are now being implemented at several of the bases Equinor operates from.

In this way, Saga Fjordbase is helping shape what future logistics on the Norwegian continental shelf will look like—in a direction that is both greener and more efficient.

25 years – and ready for the next

Today, Saga Fjordbase stands as a modern, digital, competence-based logistics company—built on values such as reliability, innovation, and teamwork. Over 25 years, the company has handled challenges, developed new solutions, and been a stable partner for the industry at Fjord Base.

The journey to where we are today shows what is possible when people, professional environments, and companies bring out the best in one another. With strong roots in the local community, clear ambitions, and a group organisation backing us, Saga Fjordbase is well positioned for the next 25 years.

Leaders at Saga Fjordbase over 25 years

- Agnar Strømsnes – the first CEO, from the company’s establishment in 2000 until 2015

- Leif Stavøstrand – took over as CEO after Agnar in 2015 and led the company through its early development years until 2018

- Erlend Toftesund – the current CEO, started in 2018 and, together with the leadership team, has positioned the company for further growth and initiated several key measures to meet the future through a focus on digitalisation, logistics competence, projects, and SMART organisation